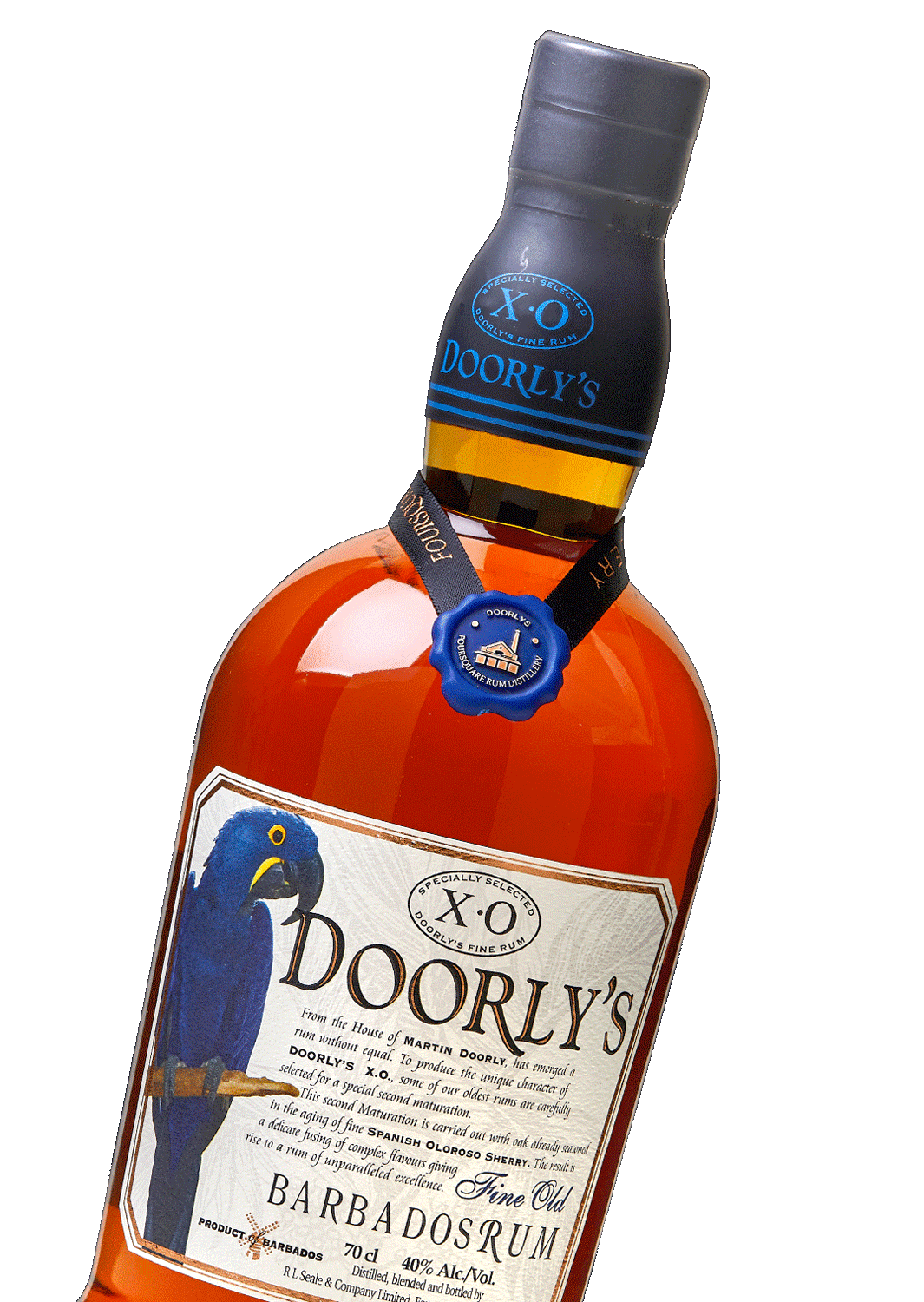

Injection moulding can be used to create a variety of 3D pieces including badges, charms and faux wax seals from plastic. Injection moulded decorations are capable of rendering intricate detail in a robust format that is available in a vast array of sizes, colours and finishes to dovetail effortlessly with your brand image.

Injection moulding involves the creation of precision-machined moulds made from hardened steel. Prototype moulds may also be made from brass. Liquid polymer is forcibly injected into the mould, where it cools and hardens to produce the finished embellishment.

A variety of thermo-setting polymers can be used to achieve different finishes, and the final product can be flexible or rigid. Ribbons and cords may be incorporated at the moulding stage to produce a fully integrated product.

We’re so happy we persevered with our goal in mind and found Signet!